The chilean pork sector commits to biogas following current sustainability requirements

Chilean pork sector companies are implementing various non-conventional renewable energy systems (NCRE) in order to move towards a sustainable world that cares for the environment and its communities. As part of this commitment to clean energy, biogas has become an excellent option. Thanks to anaerobic biodigesters, pig slurry is transformed into high-energy biogas, a tool […]

Chilean pork sector companies are implementing various non-conventional renewable energy systems (NCRE) in order to move towards a sustainable world that cares for the environment and its communities. As part of this commitment to clean energy, biogas has become an excellent option. Thanks to anaerobic biodigesters, pig slurry is transformed into high-energy biogas, a tool that the sector has been using for years.

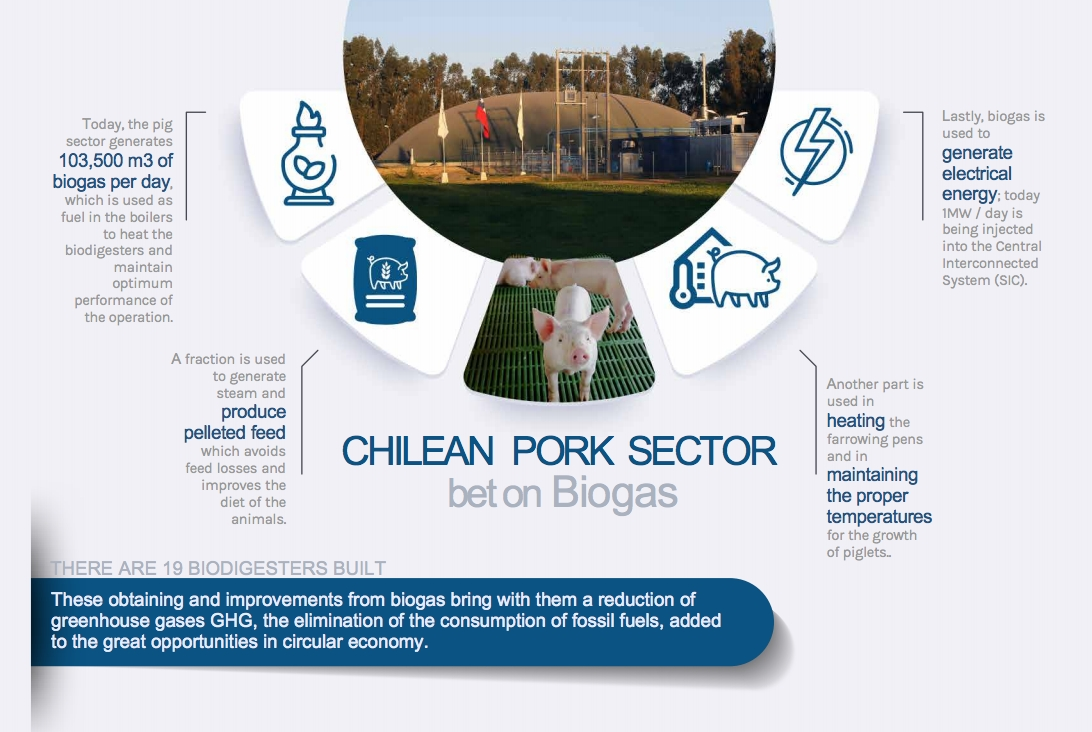

19 biodigesters built and operating in Chile

Today, the Chilean pork industry is making steady progress in its sustainable management program for the next few years because agriculture and livestock can significantly contribute to sustainability by providing clean, renewable, and non-conventional energy, as well as high-value nutrients and fertilizers for agriculture.

Currently, the pork sector has 19 biodigesters in operation and more that are being installed. Today, 103,500 m3 of biogas are produced per day, which is equivalent to producing 67,000 liters of oil per day.

Significant contribution to sustainability and circular economy

“All of this biogas-based extraction and improvements cause a reduction in greenhouse gases (GHG) and help avoid the use of fossil fuels, while creating great opportunities in the circular economy. They produce high-value agricultural products, such as stabilized organic matter and nutrients for liquid organomineral fertilizers with a high potential for use in crops, and especially for growing fruit,” explains Juan Carlos Domínguez, ChileCarne’s President.

In the next decade, Chile is expected to see an unprecedented growth in the generation and use of biogas as clean energy for many processes. Progress made in recent years points in this direction. One of the main drivers is to solve the current climate crisis caused by high emissions. As the Intergovernmental Panel on Climate Change (IPCC) stated in August 2021: “Human-induced climate change is already impacting many extreme weather and climate events in every region on Earth, but something can still be done.” A second driver is the abundance of raw material; thirdly, that this technology is increasingly available in Chile; and finally, because both large and small-scale projects can be implemented.

The pork sector has been a pioneer in sustainable initiatives

Currently, there is a large number of initiatives related to climate change, sustainability, and quantification of greenhouse gases (GHG) in different Chilean productive areas. The Chilean pork sector has been a pioneer in this area: in 1999 it signed the first clean production agreement (APL), the second in 2005, and it is currently one of the first sectors to join the Chile Conscious Origin Program led by ODEPA, the planning office of the Ministry of Agriculture (www.chileorigenconsciente.cl).

As part of this effort, the industry —via Asprocer— produces an annual inventory of greenhouse gases and reports its emissions to the Ministry of the Environment. Producers also have an online carbon footprint calculation tool that helps them improve management and processes to reduce emissions throughout the production chain.

For Juan Carlos Domínguez, “the Chile Conscious Origin Program offers a great opportunity for Chilean agri-food producers to respond to the demands of the domestic and international market and thus develop sustainable agriculture aligned with consumer demands. This is part of our mission and that is why being part of this initiative fills us with joy and pride.”

Biogas: a clean fuel with multiple industry applications

Biogas is generated during the anaerobic digestion of biomass, through a series of biochemical reactions. It mainly consists of methane (CH4) and carbon dioxide (CO2). When captured, it can be used as fuel and/or electricity. Therefore, anaerobic digestion allows to reduce and stabilize organic matter, producing both bio-fertilizers and gaseous energy, known as biogas.

Part of the biogas produced every day in the pork industry is used in the boilers to heat the biodigesters and maintain optimum operation performance. Likewise, a fraction is used to generate steam used to produce food pellets, avoiding losses while improving the animals’ diet. Another part is used for heating the farrowing pens and maintaining the right temperature for piglets to grow. Finally, biogas is also used to produce electricity. Today, 1 MW is being pumped into the Central Interconnected System (SIC) per day.